- Insights

- The Solutionists Hub

- MOQ: How to Deal With High Minimum Order Quantity for C-Parts

MOQ: How to Deal With High Minimum Order Quantity for C-Parts

I speak to C-parts purchasers all the time, so I know they have plenty of challenges to deal with during a typical day at the office. A purchaser in a role like yours needs to source the right parts at the right price, negotiate with suppliers, and make sure parts availability stays high in the manufacturing operation.

However, I’ve noticed more and more purchasers struggling with high minimum order quantities, or MOQs. The scale of the challenge that high MOQs pose depends on the size of their companies, but it’s an issue that has been affecting everyone.

Fortunately, there are ways to mitigate the high MOQ problem. This article will focus on explaining what high MOQs can mean for your company, and gives some possible approaches that you as a purchaser can take to overcome them.

What is minimum order quantity?

MOQ is a purchasing requirement that suppliers place on their customers. The definition of minimum order quantity is the minimum amount of products that a customer must order for the supplier to be willing to accept the order.

For example, imagine you need to order 3,000 pieces of a particular bolt to keep your stock at an acceptable level for the next year. You approach a supplier to purchase the bolts, but they have a MOQ of 10,000 for this item. If you want to buy from them, you'll either need to increase your order to at least 10,000 pieces or look for another supplier.

As more and more companies rely on component manufacturers in Asia, the number of purchasers affected by high MOQs grows. The reason for minimum order quantities is that these manufacturers often have tiny margins. To turn a profit, they need to sell large volumes of products. If you're not willing to accept a high MOQ, you could always pay a higher unit price – but this creates problems of its own!

What problems can high MOQs cause?

One major issue caused by high MOQs is an increased risk of obsolescence. Imagine you place an order for a specific C-part, meeting the supplier's MOQ of 10,000 pieces. If your annual usage of this particular part is 3,000, it will take you just over three years to consume the entire order. However, three years is a long time, and modern product lifecycles are short. The product may be discontinued during those three years, leaving you with a lot of obsolete components that you don't need anymore. In cases like this, your company is forced to take a loss.

Additionally, you need to consider the management of your C-parts inventory. A huge order of C-parts is going to take up a lot of space for a long time before you use it up. You need a streamlined, well-managed inventory for the manufacturing operation to run smoothly and with as little downtime as possible. This is hard to achieve if you have very high quantities of parts.

It's also important to remember that products and components kept in storage generate costs - so by the time you've used all of those C-parts, you could lose the original savings you made with the bulk order. On top of all this, these kinds of large, risky orders often require approval from your manager, which takes time out of your tight schedule.

In an ideal world, purchasers wouldn't have to battle with high minimum order quantities, but they are hard to avoid in modern manufacturing – even if there are indications that manufacturers in Asia are beginning to become more flexible. But in my opinion, with the right choice of C-parts supplier, you can reduce the impact of high MOQs on your purchasing process.

How to deal with high MOQs

An effective, practical solution for high MOQs is to consolidate and switch to a supplier who can deal with the manufacturers for you.

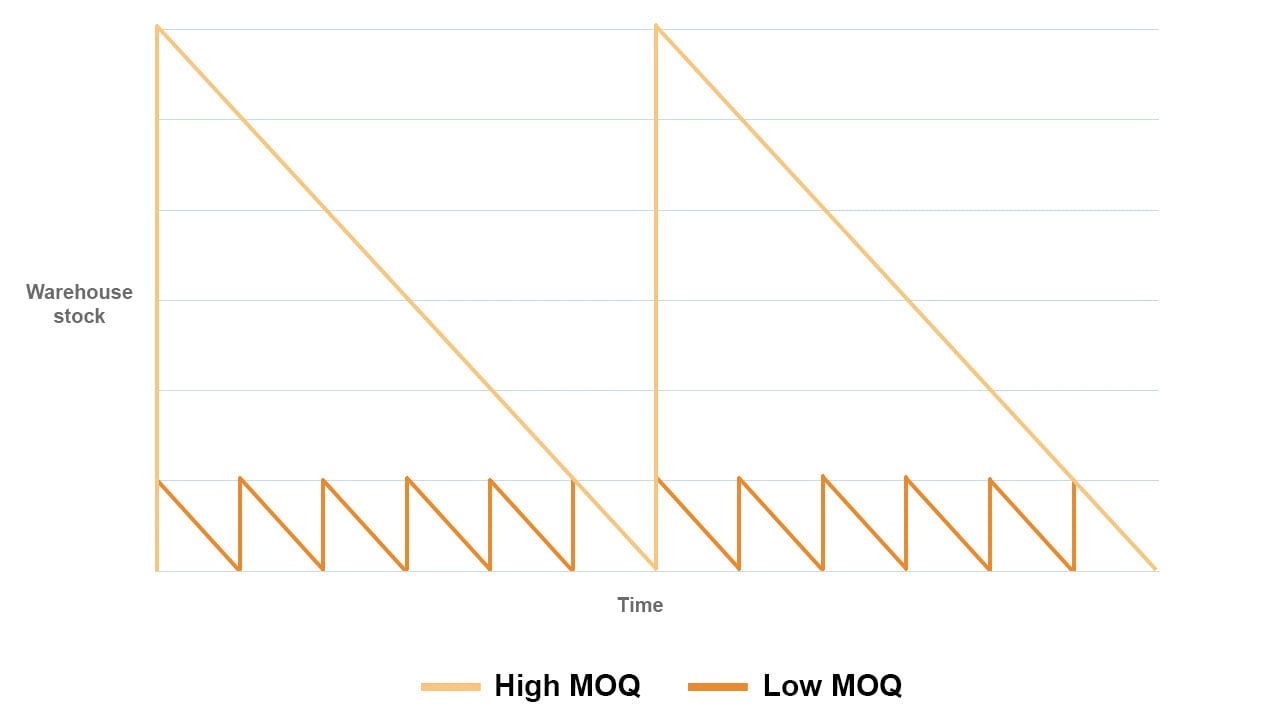

For these kinds of suppliers, MOQs still apply – they face the same problems that you do when dealing with manufacturers directly. However, a larger supplier will be able to source the parts for you and keep them on stock themselves, only delivering them to you when you need them. For example, they can make a large order on your behalf but deliver the C-parts to you over time in several deliveries of smaller quantities.

In this way, you avoid filling up your inventory with parts that you don't need right now. However, in a situation like this, you will probably remain liable for the parts that your new supplier is holding for you – leaving you at risk of obsolescence.

However, this leads to the second advantage of partnering with a larger supplier – they have other customers. If your company no longer needs the C-parts, your supplier can sell them to another customer.

If the C-parts you ordered were highly specialized and unique for your products, your supplier may not be able to do this. But by storing the parts for you and delivering them when needed, you can at least avoid clogging up your inventory and creating problems for production.

Hopefully, these tips give you some insights into dealing with minimum order quantity-related issues – if you'd like to learn more about C-parts purchasing, make sure to take a look at our guide, The Purchaser's Guide to C-Parts. It explains everything you need to know about these components and has plenty of tips on how to improve your purchasing practices.

There's also a Purchaser's Guide to Supplier Consolidation available to download – so if you're looking to streamline your supplier base and minimize the kinds of challenges described in this article, you can get it below.

Download the free guide

Get the guide to supplier consolidation

Get new knowledge every week!

Related

-

By Maria GötessonCommon C-Parts Purchasing KPIs, and How to Improve Them

-

By Oskar SvenssonVendor Managed Inventory: The Benefits of VMI for C-Parts Purchasers

-

By Jacob BergströmWhat is the Total Cost of Ownership in C-Parts Purchasing?

-

By Tuomo TiainenMy Tips for How to Succeed as a C-Parts Purchaser

-

By Carina LööfSustainable Purchasing: Guidance for C-Parts Purchasers

-

By Slawomir BieszkHow to Source C-Parts: Tips for Purchasers

-

By Slawomir BieszkC-Parts Supplier Consolidation: What Is It, and What Are the Benefits?