As a buyer of C-parts, you are responsible for ensuring that your company's production has an even supply of components that meet the specified quality and are delivered at the right time, in the right quantity and at the right price.

Manufacturing companies often focus on the high-value parts that make their products what they are. But those less-valuable, almost invisible C-parts can be just as important – and if you don't get the purchasing right when it comes to these parts, you can experience higher cost, runaway levels of administration, and even manufacturing interruptions.

In this guide, we'll focus on giving you as a buyer everything you need to know about C-parts – what they are, why they're worth focusing on, and what you can stand to gain by purchasing them in a smarter way. Enjoy.

Chapters

Chapters

What Are C-Parts?

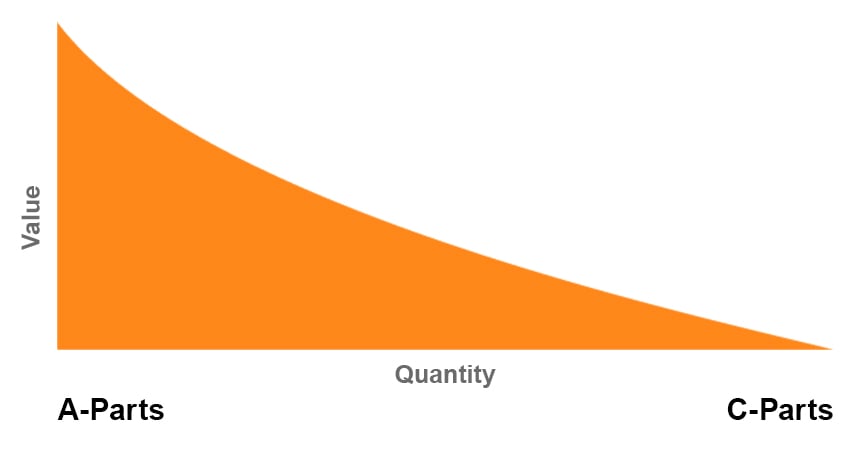

As we explain in our article 'What Are C-Parts?', you can generally split the hundreds of parts and components that go into a finished product into three categories – A, B, and C-parts.

A-parts

These are the high-value parts that go into your products. In a car manufacturing plant, engines would typically be seen as an A-part. They're likely the most expensive components in the car, and the manufacturing facility usually has relatively low quantities of them on stock.

There's also little variation in these kinds of parts – a car company may use engines of a few different sizes, but not many. Companies typically only have one or a few suppliers for these kinds of parts.

B-parts

These parts can still have a high unit cost, but they are not as expensive as the A-parts. If we look at a car plant again, components like windscreens or seats could be B-parts. Stock levels for these parts are typically higher than for A-parts.

Similarly, there's slightly more variation when it comes to B-parts. A car manufacturer may have a wide range of different seat options, for example. Additionally, companies often purchase these types of parts from several different suppliers.

C-parts

These are the lowest-value parts of all. Think screws, nuts, bolts, hinges, pipes, O-rings, and other kinds of fasteners. Don't forget that they can also be uniquely designed products such as turned, injected, extruded, stamped, forged, milled, or molded parts. The cost of an individual bolt is next to nothing, and as long as they're available on the production line, no one thinks very much about them. Many C-parts are used in very large volumes, and a large production facility may have tens of thousands of individual C-parts in stock under normal conditions.

There's a huge variety when it comes to C-parts. When you consider the need for fasteners of different sizes, lengths, and capacities, a typical C-parts inventory may hold hundreds of different SKUs.

The C-part supplier base also tends to be very fragmented. Manufacturers often buy similar components from different suppliers, typically for historical reasons. In some cases, companies can have hundreds of different C-parts suppliers to deal with.

Why C-Parts Are Important for Purchasers

Although they're not so glamorous, C-parts are still critical elements in the products your company manufactures. Without high-quality C-parts, the reliability and performance of your products would suffer.

When the quality is according to specification and they're handled effectively, C-parts become an invisible part of the production line for many manufacturers. However, their real importance only becomes apparent when something goes wrong.

The biggest problem of poor C-parts management is downtime. This is when production in the manufacturing plant has to stop, and it's one of the most expensive things that can occur in your production. During downtime, you can't produce anything – but all your production staff still need to be paid, your customers still need to be satisfied, and the lights need to stay on. Every second of unexpected downtime has a high cost, and it's one of the most severe problems a manufacturing operation can experience.

Typically, unplanned downtime is caused by machine breakdowns or human error. However, parts shortages can also be a cause. Usually, it is a shortage of C-parts – due to a large number of different C-parts with varying volumes, many companies struggle to get a centralized overview of the C-parts' availability over time. This problem can go unnoticed until it's too late. With no fasteners, items cannot be assembled, and work can't continue until new parts are sourced. And the blame often lands on the purchaser's shoulders.

Manufacturers strive to produce as efficiently as possible, and for this to happen, all needed C-parts must be available.

The Direct and Indirect Cost of C-Parts

As mentioned before, we define C-parts as the lowest-value components used in a manufacturing operation. When buying in bulk, the price of an individual fastener is a drop in the ocean for most businesses.

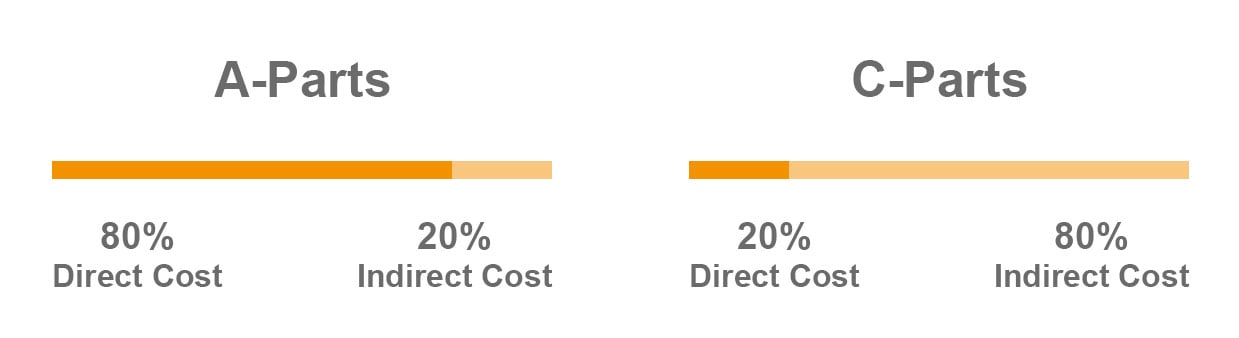

But despite their low direct cost, C-parts carry a high indirect cost. 80% of the total cost of C-parts is typically made up of indirect costs – these are costs associated with things like sourcing, ordering, delivery, handling, and inventory.

These indirect costs may be high, but fortunately, they're much easier to reduce than direct costs. It may be possible to negotiate with a supplier to get a decent price reduction on higher-value A- and B-parts, but you stand to save much more money by reducing the indirect costs of your C-parts. This can be achieved through measures like improved ordering and delivery processes, increasing parts availability, consolidating suppliers, and general improvements to your C-parts management – but we'll come to those topics later.

C-Parts and Your Total Cost of Ownership (TCO)

C-parts are often a big time sink for a business. Larger companies that haven't consolidated their C-parts suppliers can sometimes have well over 100 individual suppliers to deal with. For the purchaser, this adds up to a lot of time spent sourcing parts, speaking with suppliers, and placing orders. Elsewhere in the business, large numbers of deliveries of fairly small orders must be received and processed, and an equal number of invoices must be paid. When you add all of this time up, you realize the company is spending a lot of time and money on the simple task of purchasing fairly basic, simple parts.

When you consider all of these procurement activities, it's easy to see why C-parts carry such a high indirect cost. This is why it's vital to consider the total cost of ownership (TCO) when thinking about C-parts. A good buyer always tries to get the best possible price for the goods they're buying – but since the purchase cost of C-parts is generally low, you don't stand to make any huge savings by getting a discount.

But by factoring in the high indirect costs of C-parts during the purchasing process, you'll find other ways to make significant savings, such as through supplier consolidation. Additionally, by choosing a supplier with reliable deliveries, smooth ordering systems, and lower lead times, you cut the risk of downtime and all the additional costs that come with it.

All departments in your company, including purchasing, face pressure to reduce costs and improve efficiency. But if you realize the effect of C-parts on your total cost of ownership, you can suggest better purchasing methods that will be appreciated by both the company's management and your production colleagues.

Common Challenges For C-Parts Purchasers

Purchasers face pressure and demands from all sides – from company management, various middle managers, and the requirements in manufacturing. In this section, we'll look at three main challenges C-parts purchasers face in their daily work – and how they can be solved.

Availability

Availability is the be-all and end-all for C-parts buyers. Parts need to be available in the factory in the right quantity, at the right price, and at the right time, all the time. Factors that affect availability, such as long lead times, supplier problems, poor inventory management and poor forecasts are all realities - but they will not earn you much sympathy if production has to be stopped due to a lack of nuts, bolts or a small turned part.

Ensuring availability depends mostly on your choice of suppliers. To ensure that the necessary C-parts flow steadily into the production, your suppliers must:

- Offer quick and efficient parts deliveries

- Have a wide network of subcontractors to improve sourcing

- Use a straightforward ordering system that allows the right parts to be purchased easily

At the same time, global supply chains are incredibly complex, and anyone who has experienced the consequences of Covid knows that many global supply chains have suffered major disruptions. There are no parts suppliers who can guarantee that they are immune to these problems. But with the right partners, you can at least ensure the best possible availability for your company, given the circumstances. That brings us to our next point.

Global supplier networks

In many ways, the eastward shift of global manufacturing centers has benefited European industry – not least when it comes to cost. But at the same time, having suppliers located on the other side of the world poses problems for C-parts purchasers. The language barrier and lack of transparency make the purchasing process more difficult and prevent companies from doing proper sustainability audits.

Additionally, the already-mentioned global supply chain issues, coupled with anti-dumping regulations in Europe and high minimum order quantities (MOQs) from foreign suppliers, make the challenges of international trade even more apparent.

Again, these problems are too complex to be solved cost-effectively when you have a large number of C-parts suppliers and limited resources. But through consolidation, you can at least outsource the handling of these problems, allowing you to focus on the day-to-day realities of purchasing. You can find out how to solve MOQ-related problems in our article, 'How to Deal With High Minimum Order Quantities for C-Parts'.

Inventory management

When frustration occurs between purchasing and manufacturing, it's often due to inventory-related issues. If you as a purchaser don't have a solid picture of current C-parts stock, you won't be able to bring in the needed parts in time while also keeping stock at a reasonable level. And if manufacturing has no simple way to notify you about shortages or coming requirements, they're setting themselves up for problems. Your purchasing office and the factory floor are two very separate environments, and good cooperation is needed to ensure the required C-parts are always available.

Many purchasers have therefore seen benefits from vendor-managed inventory (VMI) powered by a suitable logistics solution. In a C-parts management system like this, the parts supplier takes over the responsibility of keeping the inventory organized and optimized. In some implementations, orders can automatically be placed for new parts when stocks drop below a certain level, taking even more work out of a purchaser's hands. Solutions like these can go a long way to smooth out inventory-related issues and prevent downtime and stock shortages.

To find out more about overcoming challenges like these, make sure to read Tuomo Tiainen's article on succeeding as a C-parts purchaser.

How To Make C-Parts Purchasing Easier

One of the most effective steps you can take to make your C-parts purchasing easier is consolidating your suppliers. This means shifting from a many-supplier model, where you order smaller amounts of parts from several suppliers, to a few-supplier model, where all of your parts needs are fulfilled by a few suppliers, or possibly only one.

As we discuss in our article on C-parts supplier consolidation, when there are too many suppliers to deal with, a purchaser's workday quickly fills up with administration. With so many unconnected contact points, they must spend a lot of time coordinating them and keeping an eye on inventory. In this situation, it's likely that things get overlooked or missed – which in the worst-case scenario can lead to parts shortages and result in downtime, not to mention the brand damage caused by a missed customer delivery.

Additionally, when you have a large number of minor suppliers instead of a few major ones, it's hard to build up a business partnership with them. The quantities they sell to you are often so small that they probably don't want to spend too much time keeping you satisfied. Over time, this can lead to higher procurement costs, poor communication, and in the worst case, unnecessary delivery and quality problems.

Many common purchasing problems can be blamed on having too many suppliers. That's why supplier consolidation is such an important topic. It can be challenging to switch suppliers, and the task of moving from many suppliers to only a few isn't easy. But when you consider the bigger picture, you can save time, money, and resources by starting to consolidate.

Get the Guide to Supplier Consolidation

Put simply, supplier consolidation is an excellent way to improve your C-parts purchasing process. However, it's also filled with challenges. We've made an introductory guide to supplier consolidation aimed at purchasers like you to make things easier. It contains some valuable tips about what to think about when consolidating suppliers, the different approaches you can take, and even the potential drawbacks of consolidation. Click below to get it.

Download the Guide