The management of C-parts is a time-consuming and costly affair for most companies. Thus, you can obtain cost reductions and efficiency by improving the supply chain management of C-parts.

The purpose of this guide is to give you and your executive management an understanding of the business-critical opportunities that C-parts management entails. If you want to learn more, you can download the guide on how to implement a seamless supply chain of C-parts.

Chapters

Chapters

What is Supply Chain Management?

Supply chain management is the handling of production and material flow, from raw materials to the final product. When manufacturing and distributing a product, most companies are dependent on an extensive network of suppliers. The objective when improving supply chain management is to coordinate the network of suppliers to achieve the desired result.

Components of supply chain management

Supply chain management consists of five components; plan, source, make, deliver, and return.

Plan

To ensure your supply meets the demand for your product, you need thorough planning.

Source

There are many parts needed to manufacture the final product. An essential component of the supply chain is to choose the suppliers to buy from.

Make

When the parts arrive at your factory, you need to have processes for manufacturing the product. This includes quality assurance, replenishment, and ensuring a constant supply of components.

Deliver

When your final product is ready for distribution, you need to have the right processes of coordinating orders, deliveries, and invoices.

Return

The final component refers to having a process for products that are being returned from customers.

How these different components actually work can vary from company to company - read this article for more insights into how the process can look in practice.

What are C-Parts?

All components used in a product fall into three categories, also known as the ABC analysis, commonly used in inventory management:

A-parts are components with the highest value.

B-parts are components with intermediate values.

C-parts are components with the least values.

Definition of C-parts

Typical examples of C-parts are fasteners, anchors, bolts, hardware, nails, nuts, pins, clips, rivets, rods, screws, sockets, clamps, hangers, O-rings, and washers, but it could also be uniquely designed products such as turned, injected, extruded, stamped, forged, milled, or molded parts. They are all components with a low value to the end-product, but still just as crucial to the manufacturing and function as A-parts.

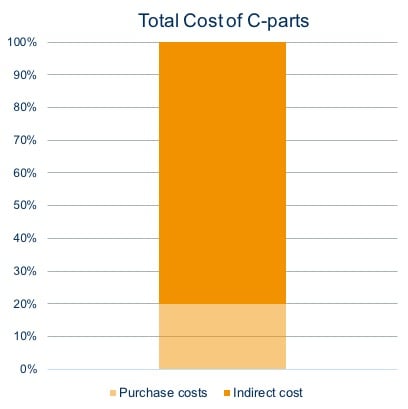

The indirect cost of handling C-parts is often much higher than the direct price. Not seldom, the purchase price is only 20% of the total cost. The remaining 80% are indirect procurement costs such as sourcing, planning, logistics, and quality measures.

What is Supply Chain Management of C-Parts?

Supply chain management of C-parts is the handling of C-parts in the production flow. As this usually is a product category with high volumes, companies are often relying on an extensive network of C-Part suppliers. Thus, there is a need to coordinate the suppliers to minimize cost, waste, and time.

C-parts management

As described in the above section, Components of supply chain management, general supply chain management consists of five components. When talking about C-part management, in particular, it is essential to look into the three pillars; plan, source, and make.

Plan

C-parts are critical in the manufacturing process. If you run out of fasteners, for example, your production will most likely stop. Thus, many companies buy and stock more C-parts than they are in need of. That is a costly tactic. By planning your future demand for C-parts, there is a vast potential for minimizing cost, waste, and time.

Source

A large part of the supply chain management of C-parts is sourcing suppliers and negotiating prices. To build an effective supply chain, you'll need a broad supplier base to choose from.

Make

To keep production going, you need to ensure a constant supply of C-parts. You need a well-thought-out process for quality assurance, replenishment, and placing new orders.

Why do C-Parts matter for Executive Management?

C-parts are often overlooked by executive management. Although fasteners, a screw, or a turned part have a low value, they are critical for the end product. In fact, the majority of your inventory levels probably consist of C-parts.

As previously stated, the purchase price is only a fraction of the total cost of ownership for C-parts. Thus, companies that approach C-parts as a management matter often discover huge cost-saving potential when implementing an evolved supply chain management strategy.

What is the cost of managing C-parts?

The procurement processes of C-parts can be classified into three categories; sourcing costs, quality costs, and logistic costs.

Sourcing Costs

- Supplier sourcing

- Evaluation

- Verification

- Negotiation

- Supplier administration

- Parts administration

- Phase-out/phase-in costs

Quality Costs

- Costs of preventive quality measures, such as SQA

- Corrective quality measures, such as scrap and rebuild

- Indirect costs of quality such as line stops and rescheduling

Logistics Costs

- Forecasting

- Planning

- Ordering

- Incoming goods handling

- Inspection

- Warehousing

- Stock control

- Internal transports and line feed

- Freight

As the indirect costs make up 80% of the total cost, you should consider C-parts as a management matter. Building better supply chain operations for C-parts will require decision-making and support from the top management.

What are the Challenges of Managing C-Parts?

In an ideal world, every little detail is there when you need it, and the production moves on smoothly. However, the real world is often a different story. The employees who handle C-parts face several challenges, increasing inefficiency and risks for the organization. Below we look at the main challenges that make C-parts a costly affair.

Sourcing suppliers

When it comes to C-parts, most companies require customized parts, and thus, it can be time-consuming to find the right supplier.

Multiple suppliers

Depending on the size of your organization, you may have dozens or hundreds of suppliers to deal with. Dealing with multiple suppliers requires a lot of administration for the people in the purchasing, logistics, and planning departments.

Lead times

Many companies lack accurate data about the stock levels for C-parts. This makes it difficult to predict future demand. With poor forecasting, many suppliers and unstandardized products purchasers are often faced with challenging lead times of C-parts.

Quality assurance

Sourcing high quantities from multiple suppliers complicates the quality assurance of C-parts. Many organizations state that this is a common challenge with managing C-parts.

Climate emissions

Supply chains account for a large part of companies' total climate impact. The more suppliers, the more transportation and ultimately higher climate impact. As sustainable supply chains become a top priority among global companies, the increased emissions from C-part deliveries are a growing concern.

For more depth on this topic, take a look at our articles on overcoming your supply chain challenges and managing the risks that they are associated with.

What are the Risks of Supply Chain Management of C-Parts?

The challenges of traditional supply chains contribute to significant risks for manufacturing companies. To develop strategies that mitigate risk, executive management must have a profound understanding of the exposure, vulnerabilities, and potential financial loss that are related to the supply chain of C-parts.

For several decades companies have developed and organized complex supply chains. Intending to reduce costs, minimize inventory, and increase efficiency, most manufacturers rely on global networks of suppliers. Until the beginning of 2020, this model guaranteed a smooth flow of deliveries, and the production could move on as expected. But abruptly, the pandemic outburst would reveal some severe structural flaws in the traditional supply chain.

Today, most industries have been affected by disrupted supply chains. Disturbances such as factory shutdowns, limited transportations, and increased raw material prices are closely correlated.

How to Improve C-Parts Supply Chain Management?

Companies that work actively with C-parts management achieve better conditions to overcome the challenges and mitigate the risks with C-parts.

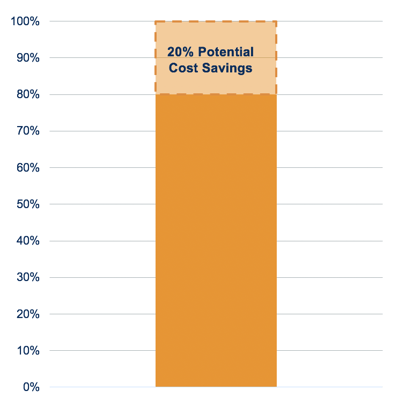

C-part management is an approach to reduce the total cost of C-parts while ensuring a constant supply of components. Companies that don't work to streamline the handling of C-parts end up spending too much time and money on procurement costs. By building a better supply chain for C-parts, you can typically reach a cost reduction of more than 20%.

How to Build a Better Supply Chain for C-Parts

There are many ways to achieve an improved total cost of ownership, and the best method for you depends on the industry and company size. But a measure that gives quick and effective results is to consolidate both components and suppliers.

Supplier consolidation

Having multiple suppliers forces you to handle multiple negotiations, quality assurance, logistics management, and other administration-related costs. By reducing the number of suppliers, you can thus achieve up to a 20% reduction in the total cost of ownership.

In this article, you can read more about what to consider when choosing between a supplier or a supply chain partner

Product consolidation

If you have a large number of C-parts, there is often the opportunity to reduce costs by using a Supply Chain partner who already has this type of products in their existing portfolio and where the logistics chain is optimized and quality assured.

If you can limit component types, you can order larger quantities and benefit from economies of scale.

Get the Guide to a Seamless Supply Chain of C-Parts

Do you want guidance on how to implement a seamless supply chain of C-parts, where every detail is there when needed, and production moves on smoothly?

We have created a guide for your executive management explaining what a seamless supply chain of C-parts is, why it's important and how to achieve it. Download the guide below, and explore the steps to implementing a seamless supply chain of C-parts today.