- Insights

- The Solutionists Hub

- C-Parts Supplier Consolidation: What Is It, and What Are the Benefits?

C-Parts Supplier Consolidation: What Is It, and What Are the Benefits?

As manufacturing processes and product designs become more complex, many C-parts purchasers I meet have to deal with more and more suppliers. In some cases, it's because they need highly specialized components. In others, they want to increase the redundancy of their supplier networks in a time of supply chain disruptions.

However, as a purchaser, you'll know that having too many suppliers can be a problem. It can lead to higher levels of administration and watered-down relationships, which can have severe consequences for your company as a whole.

A solution to this issue is supplier consolidation. In this article, I'll aim to help you understand what supplier consolidation is, how it works in practice, and what the benefits could be for your purchasing department.

What is supplier consolidation?

Supplier consolidation, sometimes called vendor consolidation, is the process of reducing the number of supplier companies you buy your goods from. The quantity and types of items you purchase remain the same, but you buy them from a smaller number of suppliers. In effect, it's a rationalization process aimed at boosting efficiency and cutting costs.

In a typical manufacturing company with an unconsolidated supplier base, a C-parts purchaser may buy nuts and bolts from one group of suppliers, screws from a second group, cables from a third, and milled parts from a fourth. In total, this can easily add up to 20, 30, or more suppliers who are all supplying the same company.

If a company like this consolidates its supplier base, it can still buy the same amount of C-parts, but from fewer suppliers, each supplying a wider range of components. After consolidation, the number of suppliers could shrink to only a handful – or even to one, depending on the company’s requirements.

How does supplier consolidation work in practice?

Whether you choose to consolidate your parts needs with one of your existing suppliers or an entirely new one, the process should follow these main steps:

- Analysis

- Implementation

- Evaluation

Analysis

In the analysis stage, the supplier should work with you to understand your C-parts needs. To be an effective partner, they need to know what kinds of parts you use, what quantities you require, how you store them, how you take deliveries and the details of your ordering process. Without understanding the basics, they'll struggle to implement a better supply base management approach.

A good supplier should always consider the KPIs that your purchasing department and manufacturing operation need to meet so that they can work with you as effectively as possible. They should also be able to present you with a clear business case for their proposed solution.

Implementation

In the implementation stage, you put the agreed-upon approach into effect. Implementation is a sensitive process since your C-parts needs are complex. That's why the actual implementation should always be preceded by careful mutual planning. In many cases, it is beneficial to take a step-by-step approach. Divide all the C-parts into categories, and work with one or a few categories at a time.

Evaluation

The evaluation stage is vital. After implementing the new solution, you and the supplier should assess its performance and agree on what needs to be changed. No matter how smoothly the implementation goes, it's likely that there will still be particular areas that need to be improved. Once the evaluation is complete, the changes are implemented.

If you choose a knowledgeable, effective supplier, this evaluation stage will likely continue throughout your partnership. They should meet with you regularly to analyze the state of your operation and get updates on future plans so that further improvements can be suggested, implemented and measured.

What are the benefits of supplier consolidation?

For most of the purchasers I speak to, the main benefit of a consolidated supplier base is the reduced levels of administration.

If you work with, for example, 30 C-parts suppliers, you probably face a lot of repetitive work. You need to source parts, negotiate prices, organize deliveries, and deal with invoices and any potential problems with 30 different companies, many of whom are spread out across the globe and have little knowledge of your company's particular requirements.

This work can consume a large part of your workday – and when there are so many suppliers to keep an eye on, problems can quickly arise. In many cases, these problems simply result in another headache that you need to solve. But in the worst case, this kind of disjointed approach can lead to unexpected parts shortages, resulting in downtime in the manufacturing operation. No production line should have to stop because of something as simple as a shortage of fasteners or other C-parts. Still, I've seen it happen in many companies – and in most cases, it's due to a disorganized and disjointed supplier base.

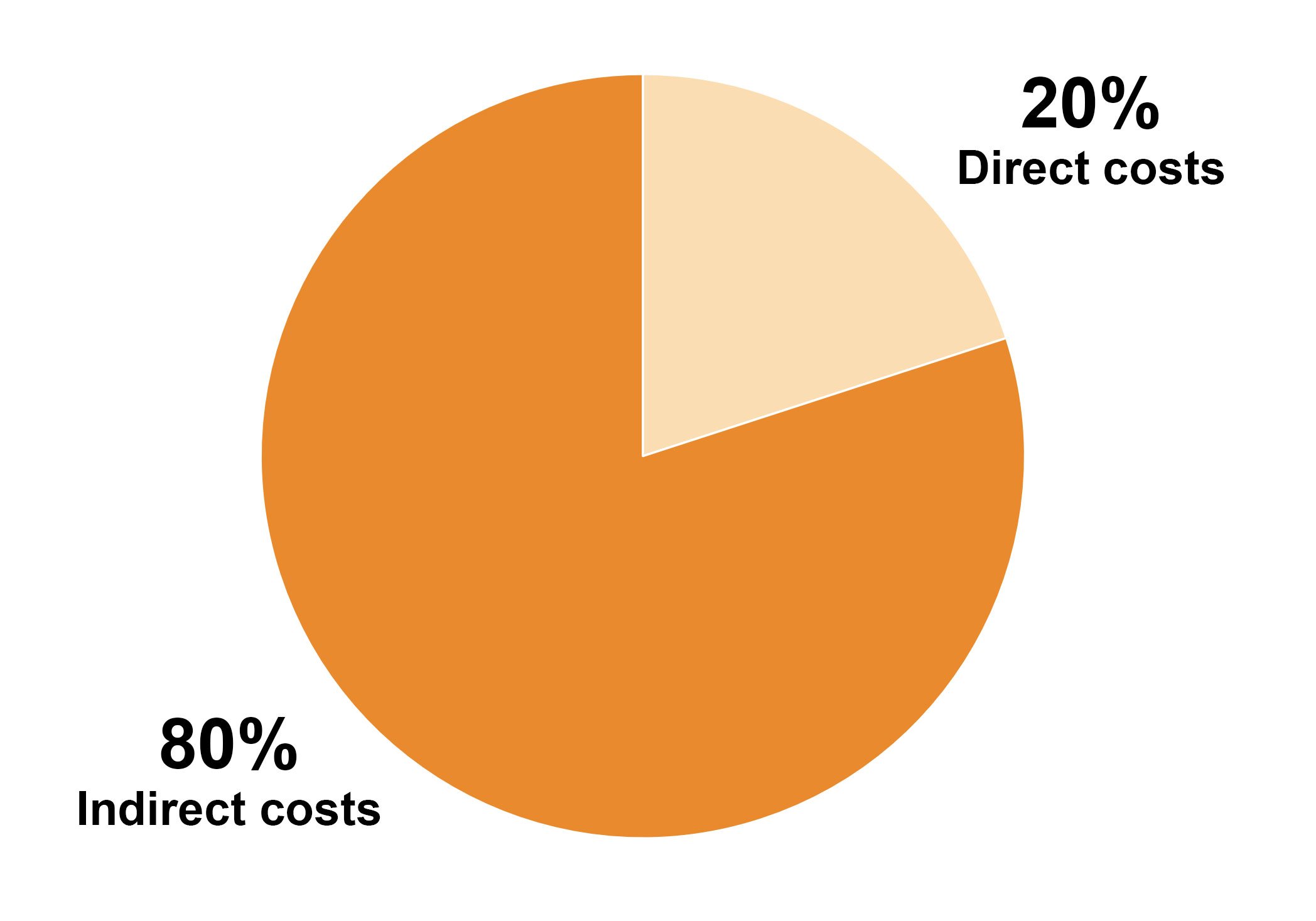

There’s also significant costs that come with having lots of suppliers. Around 20 percent of the total cost is made up of direct costs – in other words, the cost of the C-parts themselves. The remaining approximate 80 percent are indirect costs, which are much easier to bring down. Indirect costs can include things like the cost of sourcing, ordering, receiving orders, and dealing with invoices. By reducing the supplier base, you can reduce the amount of time spent on these tasks and save money in the process.

Consolidating suppliers makes it much easier for you to get an overview of the total flow of C-parts into your operation. In practical terms, this means less administration, fewer costs and better outcomes for the business.

Additionally, a reduction in suppliers makes it easier to build a tight, effective relationship with them. If you're dealing with over 50 suppliers, you probably don't have enough time in the day to develop a solid business relationship with either of them. And since the breadth of your supplier base means you're making pretty small orders from each one, there's a chance they won't be so interested in keeping you satisfied.

By consolidating, your number of supplier contacts drops, and even if your C-parts needs remain the same, you'll become a more significant customer for the new supplier. You can spend more time working closely with each one, and they can get a better picture of the needs of your business. Over time, these improved relationships can lead to better prices, better solutions, and better performance.

Get the Purchaser's Guide to Supplier Consolidation

If you are experiencing problems caused by having too many suppliers, or if you are facing the challenge of reducing the size of your company's supplier base, you should take a look at this guide. If you do not feel you have the need, you may want to read the guide anyway. It develops on the issues I've spoken about here and gives more details about the benefits of consolidation, how your consolidation process could actually work, and some potential approaches to consolidation you could take. It even discusses the potential drawbacks that consolidation can pose – and the solutions you need to get around them. You can download the guide as a presentation below.

For more knowledge about C-parts, read our Purchaser’s Guide to C-Parts – it goes into more detail about what C-parts are and why they’re so important in your purchasing work.

Download the free guide

Get the supplier consolidation guide

Get new knowledge every week!

Related

-

By Maria GötessonCommon C-Parts Purchasing KPIs, and How to Improve Them

-

By Oskar SvenssonVendor Managed Inventory: The Benefits of VMI for C-Parts Purchasers

-

By Jacob BergströmWhat is the Total Cost of Ownership in C-Parts Purchasing?

-

By Tuomo TiainenMy Tips for How to Succeed as a C-Parts Purchaser

-

By Carina LööfSustainable Purchasing: Guidance for C-Parts Purchasers

-

By Slawomir BieszkHow to Source C-Parts: Tips for Purchasers

-

By Slawomir BieszkMOQ: How to Deal With High Minimum Order Quantity for C-Parts